Company Insight

Sponsored by Nord-Lock Group

Superbolt® strut kits for heavy haul truck maintenance

Standfirst...

Main image credit:

Superbolt’s technology has been proven in tens of thousands of successful installations and we continue to develop a multitude of solutions to solve the next generation of bolting challenges.

The strut concept is approved on larger trucks by the OEM, already proving the benefits on the largest and most critical components. This technology is used globally and has had zero bolting failures in 15 years.

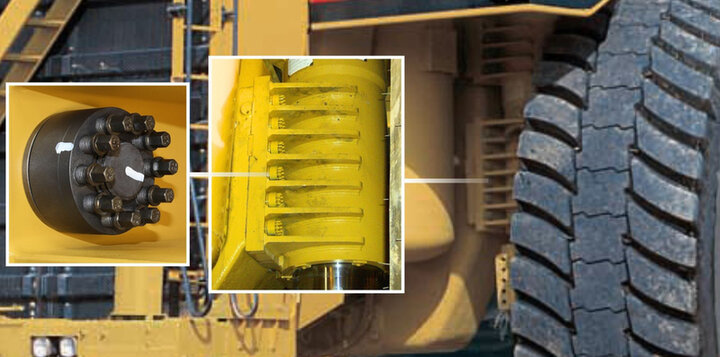

The Superbolt® strut kits helps to simplify and streamline your mining haul truck maintenance. Our innovative technology allows the mounting hardware for one front suspension strut assembly to be installed in under one hour. Superbolt Multi-Jackbolt Tensioning (MJT) take high preload requirements and break them down into manageable torques, and provides high accuracy in tightening joints without requiring specialized skills or heavy tooling.

Caption. Credit:

Complete kitted solutions. Complete peace of mind.

Superbolt kitted solutions for heavy mine haul trucks deliver all the benefits you need in a complete, high-quality kit, including:

- Innovative Technology for working within tight spaces

- Superbolt MJTs take high preload requirements and break them down into manageable torques

- High accuracy in tightening joints, without requiring specialized skills or heavy tooling

- Only the need for simple tools – no heavy/cumbersome equipment

- Easy installation with just one or two workers

- Safe and easy to work with, especially compared with the alternatives

- Minimal input torque required for successful installation

- One strut kit can be tensioned in under one hour with simple hand tools

- Simplified maintenance for ongoing cost savings

- Increased reliability throughout

- Drop in replacement – ready to install out of the box

Our kitted solutions for mining heavy haul trucks are reliable, quick and easy-to-install - decreasing your machine's downtime and saving you money!

Customer case study

The world's leading mining companies count on Superbolt to consistently deliver the safest and highest-quality solutions for their demanding environments.

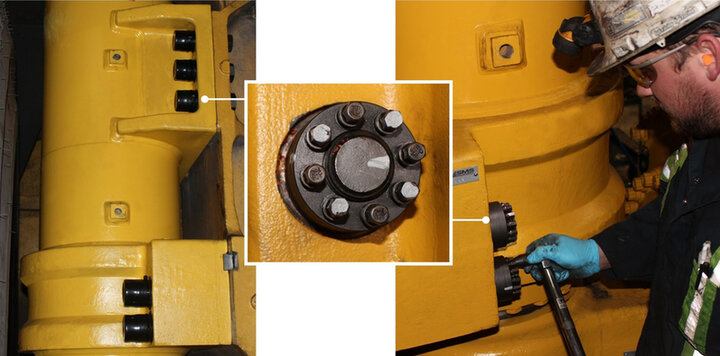

For Caterpillar heavy haul trucks

Caption. Credit:

The Superbolt solution of MJTs, studs and Flexnuts was first installed as an active field test for a mining customer on one of their Caterpillar™ 797s in 2007. The target was to increase the average service life of the bolting by 2.5x — from 800 to 2,000 hours.

The Superbolt solution exceeded the target greatly and this led to the customer changing the entire fleet to Superbolts, thus improving reliability by securing the strut through it’s 18,000+ hour life cycle. With a 22.5x improvement in the life cycle, customers are already seeing a reduction in costs.

A longer life cycle means more savings!

For Komatsu heavy haul trucks

Caption. Credit:

A Superbolt suspension kit was recently installed on a Komatsu™ 960E mine haul truck in central

Queensland, Australia.

It only took two workers (using safe and easy hand-held tools, with low-input torque) to install the Superbolt suspension kit all in under one hour! The customer’s previous method took four to six hours, utilizing three technicians.

The problem with traditional strut bolting: | The Superbolt strut bolting solution: |

|

|

Superbolt has proven strut kits for various haul trucks in the mining industry help improve access to bolting, reduce safety risks, and prevent tooling slippage. The result? Significant savings on repairs and downtime—thanks to our durable, high-performance kits. To date, thousands of kits installed globally with zero failure rate and we’re proud to deliver 100% customer satisfaction every time.

Join us at the IMARC 2025, Stand G23, from 21 – 23 October 2025, ICC Sydney Australia.

Contact information

Nord-Lock Group

CK Energy Services Pty Ltd

(Authorized Distributor for Nord-Lock Group)

Keith Howlett

Tel.: +61 416 885 944

Email: keith.howlett@ckenergy.com.au

Expander

Paul Yoong

Tel.: +61 449 258 829

Email: paul.yoong@nord-lock.com

Superbolt, Inc.

Steve Brown

Tel.: +61 414 586 417

Email: steve.brown@nord-lock.com

Web: www.nord-lock.com