COMPANY INSIGHT

Sponsored by Aerometrex

How aerial surveys benefit your mine site through its entire life cycle

Aerial imagery, 3D modelling and LiDAR benefits your mine site through its entire life cycle. From pre-build planning to post-operation rehabilitation, getting accurate and regular captures of your site makes a more profitable, efficient, safe, and compliant mining operations.

A

erial surveying has grown in popularity within the mining industry for a good reason; they simplify all tasks that depend on the precise measurement of large areas. Mine sites change constantly and rapidly and have stringent planning, safety, reporting, and efficiency requirements. Our services and client list has grown to reflect the modern operational needs of mine sites.

Below we talk about how our aerial surveys, modelling, and measurement services support mining operations.

Services at a glance

With our aerial surveys we can:

- Use multispectral 4-band near-infrared imagery as a powerful change measurement tool for your site.

- Capture your whole site with no disruption to operations.

- Calculate volumetric and stockpile analysis.

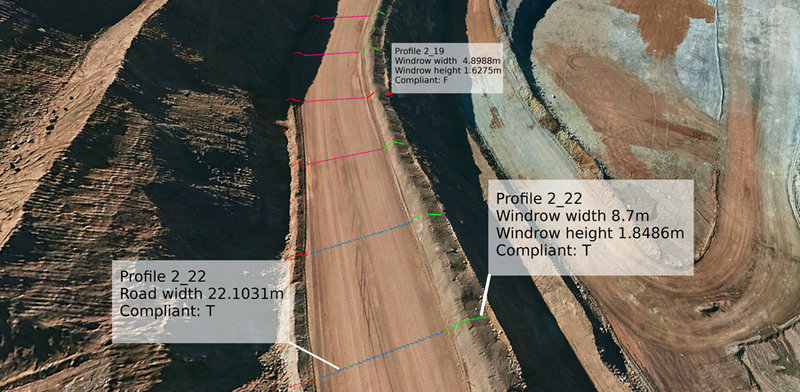

- Validate the safety and compliance of your haul roads and windrows.

- Get the best data to build a 3D model for engineering design and site construction planning.

The ultimate planning and site management tool

Aerial surveys are a fast and non-disruptive way to measure and capture your mine site. We can use both high-density LiDAR and aerial imagery depending on your site needs. Get the most accurate baseline data to start your planning and model the entire area.

A 3D Reality Mesh Model with LiDAR measurement data is the perfect starting point for engineering operations, construction, project planning, and communication activities. Use an accurate and fully textured 3D model of your site as a simulated planning sandbox. Model all your future development and carry out virtual re-designs. Communicate better with your stakeholders using a 3D model to show what you’ve done, are doing, and are planning to do in the future.

LiDAR adds the high-accuracy measurement that can enhance the imagery from 3D Reality Mesh. Build precise Digital Terrain Models (DTM), Digital Surface Models (DSM), and digitised 3D feature data. You can analyse surface features and predict underground deposits from aerial imagery. Strip away all above-ground structures and vegetation to see accurate DTMs. Add contour measurements for elevation context.

Get your LiDAR point cloud or 3D reality mesh “classified” so every object on your mine site is identified and given attribute data. Make buildings, structures, different surface types, and vegetation clear and isolatable. Enrich your classified 3D model with any database information. You can add detailed information on any classified feature for a more visual site management system.

Assess rock faces with our high-resolution imagery. The quality of our captures and 3D modelling allows rock structure and geological units to be identified without having to inspect on-site. See exactly where and how the rock walls have changed.

// Assess rock faces and geological units with high-resolution imagery

Safety

Our captures can measure and assess your windrows and haul roads to make sure your site is safe and compliant. Our Windrow Analysis Tool measures height, width, and slope of windrows calculated from elevation profiles. The tool removes the need for manual digitisation of your site features. Take the guesswork out of windrow safety.

We give a full report, including shapefiles on road segments, windrow lines, and road profiles. Keep your site operating smoothly and safely with well-made haul roads and windrows.

All of our aerial work makes for a safer working environment. Not only from planning and site management, but from fewer people manually measuring on-location. We capture while the mine is fully operating.

// Assess the safety and compliance of your windrows and haul roads

Volumetric analysis and site change measurement

Quickly calculate and analyse volumetric data and stockpile size to measure cut & fill and simplify other environmental and compliance reporting. We have dedicated mining industry services that do site capture and volumetric analysis with a typical three-day turnaround time to keep your reporting accurate and current. We do all volumetric measuring with aerial imagery or LiDAR, which means no presence on-site.

Multiple captures over time let you see and measure how the site has changed.

// Quickly calculate volumetric data and stockpile size

Environmental monitoring and rehabilitation

Our LiDAR and aerial imagery assess and monitor vegetation health and help plan for rehabilitation. The multispectral 4-band near-infrared imagery we capture shows chlorophyll content in vegetation, which indicates overall plant health. LiDAR can measure vegetation density from tree canopy to ground. Changes in vegetation levels are made trackable over time.

We help you meet environmental requirements for your site:

- Environmental risk assessment and management.

- Regulatory and approval requirements.

- Investigate environmental incidents and implement corrective actions.

- Undertake monitoring where required.

- Environmental data reporting and submissions.

- Environmental performance auditing and inspection.

// Near-infrared imagery lets you analyse vegetation health