company INSIGHT

Sponsored by: Engineering Plastics

Specialised plastics for the mining industry

Since 1972, Engineering Plastics has produced some of the finest examples of polyurethane components within Australia. We have specialised over the years in the manufacturing of Polyurethane elastomeric products. We have expanded our versatility by introducing new product lines and services. These include a variety of Structural (hard) Plastics; Commercial Grade Elastomers (Rubbers) and Industrial Composite materials.

Engineering Plastics is a company with complete drawing and design, engineering, tooling and fabrication capabilities. We can handle all jobs too, whether they come with big or small specs attached. This means you can count on us as a true one-stop shop, geared to saving you valuable time and production costs.

Why Choose Engineering Plastics?

When you visit Engineering Plastics, you won’t see any fancy workspace or plush office suites. Instead, you’ll find a powerhouse of engineering workshops bursting with the latest technology and situated behind an unassuming façade. To give you a guided tour might take a while, but here’s a brief list of the capabilities we have on board.

IMS Overfill Prevention System Masterfile

Rockwell Application solution overfill-prevention system

Expert Hands On The JOB

First of all, you get to work directly with engineers who are hands on with the job. Our chief consultants are skilled in taking your project, whether big or small, from discussion brief through to specs and drawings. If there is tooling required our pattern makers will design the right dies and casts for the job. In fact, we can even save you money by producing tooling to replace costly imported polyurethane components. Ask us for further details.

First of all, you get to work directly with engineers who are hands on with the job.

When Experience Counts

From experience, we can offer you a guarantee on our work if we have the right specifications for the job from the start. That’s an indication of the value we place upon our output at Engineering Plastics. And given the fact there are so many variables in the work we do, we take the time to discuss all the details from the start by mapping out exactly what you require. You can rest assured the final product is manufactured using the highest quality polyurethane and rubber around.

IMS Overfill Prevention System Masterfile

On Schedule And Within Budget

Once we get the nod to proceed, you are kept updated at each stage of production. In fact, part of our brief is to stay in regular contact. This means you can have complete confidence in the job running to schedule and within the budget specified.

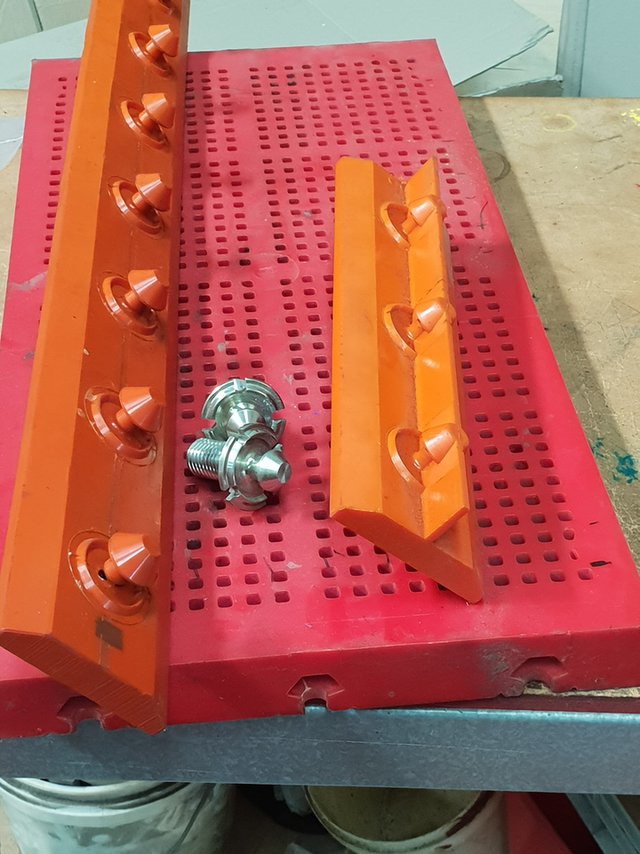

Engineering Plastics has been producing bespoke screening solutions, and patented bolt-on rail and fixing systems for more than 20 years.

Our Products

Engineering Plastics supplies polyurethane elastometric products, hard plastics, commercial grade rubbers and industrial composite materials for the mining, agriculture and road transport sectors.

Our products include trommel and flip-flop screens, Elastoloc and divider panels, locking rails, agitators, chute and pipe linings, and moulded rubber screens.

Engineering Plastics has been producing bespoke screening solutions, and patented bolt-on rail and fixing systems for more than 20 years. Our polyurethane products weigh between 10g and 400kg and range from 10A to 80D hardness grades, enabling us to meet any client requirement.

We also manufacture ultra-high-molecular-weight polyethylene (UHMWPE) thermoset plastics, high-performing nylons, acrylics, polycarbonates and rubbers, as well as offer complete drawing, design, engineering, tooling and fabrication services for any job.

Engineering Plastics offers high-quality polyurethane sheet products for domestic and commercial applications.

We have a wide selection of options available, including high-density polyurethane and rubber sheet products.

Our polyurethane sheets offer various benefits, including:

- Significant electrical properties and environmental stability

- High levels of flexibility and cost-effectiveness

- Highly resistant against mould, mildew, fungus, water, oil, grease, abrasion, solvent, impacts and damage

Our polyurethane sheet products can be used for various Mining applications, including bearings, gaskets, seals, wheels, noise dumpers, slurry transfers and drive belts.

Special custom sizes can also be manufactured to meet your specific requirements.

We also offer VR polyurethane panels that have high abrasion-resistance and do not blind or peg in operation, as well as easy-to-install trommel screens for feed, centre and discharge ends.

We use the highest quality material to ensure a long service life.

IMS Overfill Prevention System Masterfile

Engineering Plastics manufactures pipe linings and polyurethane-coated pipes for slurry applications.

We can coat pipes up to 6m-long and large diameters to provide wear-resistant solutions for the grain processing and mining sectors.

Engineering Plastics is a leading provider of polyurethane moulded products and in-house tooling.

Our moulded solutions range from cable slide guides and concrete pattern stamps through to rubber screens and stock rods.

Engineering Plastics specialises in custom equipment for various industries, including Mining, Railway and Manufacturing.

We use a variety of plastics to create polyurethane roller and pulley products in a range of hardness grades.

Our pulleys are available with a safe working load (SWL) of up to five tonnes and our polyurethane rollers can be manufactured with or without a coating.

We can also provide custom plastic products such as lifter bars to save money in the wood industry, as well as chain guards for lifter bars. Our supply of rollers even extends to plastic film stretch rollers, which we can design on request to your specifications.

More than half of the country’s coal mines are managed by pro-Russian separatist militia. Credit: DmyTo/Shutterstock.

Contact information

Engineering Plastics Pty Ltd.

No 2 Stezlecki Grove

Laverton 3028

Australia

Telephone: +61 93692577

Fax +61 93697117

Mobile: +61 412639117

Email: enquiries@engplastics.com.au

Eero Knuutila is Head of Service Development at Helsinki Airport.

Image courtesy: Helsinki Airport