Watch our company video

Visit our website

Torque limiters for conveyors

Drum Couplings for conveyors

Torque limiters for crushers

Gear Couplings for all applications

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM

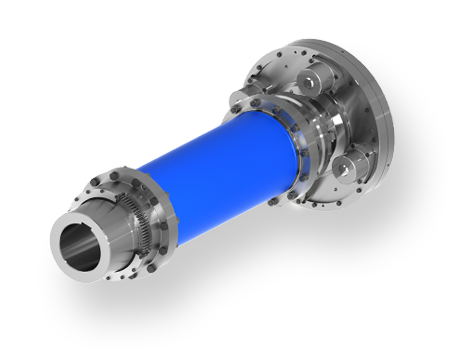

A new concept for Conveyor Belt Drives:

The MALMEDIE SE-E type coupling

More and more conveyor belt drives worldwide are being modernized by retrofitting the motor controls with Frequency Drives for a soft start instead of using fluid type couplings. There are many reasons for this, one of which is the fact that Fluid Couplings can have a transmission slip of up to 20%. This slipping consumes energy…so the conversion to frequency controlled AC drives can save on considerable energy costs.

In many of these retrofit cases, an important factor is often overlooked. The Fluid Coupling had an additional purpose besides acting as a soft start. It also offered overload protection for the drive torque. MALMEDIE has developed a solution for these types of applications. A MALMEDIE Safety-Coupling which is combined with a torsionally stiff but flexible drive shaft.

The MALMEDIE Safety-Coupling offers peak torque protection of the drivetrain by completely separating and removing the drive forces within milliseconds (no friction, no wear). Simple and fast re-setting of the coupling is done by simply pushing the pins of the Safety-Elements back into place. An automatic re-set option is available. The MALMEDIE Safety-Coupling is built in a Heavy-Duty Execution for the most extreme conditions and duty cycles.

Visit our website

Back

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM

Not just for Rope-Drums:

The MALMEDIE TTXs type coupling

Barrel-Type Drum-Couplings (invented by MALMEDIE back in 1958) are specifically designed to handle radial loads as well as the torque load. Radial loads exist on hoist rope drums due to the rope pull – but they also occur on conveyor belt pulleys due to the belt tension.

With the MALMEDIE TTXs Drum-Coupling, conveyor belt pulleys can be connected directly to the gearbox output shaft(s). Belt pulley support pedestals/bearing at the gearbox side are no longer required. This results in a more compact design and cost saving!

Visit our website

Back

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM

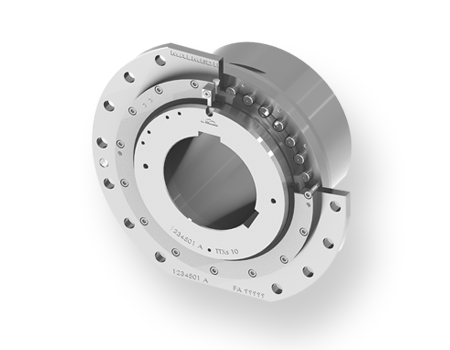

The robust one for crusher drives:

The MALMEDIE SE-GLX type coupling

Torque limitation is of the utmost importance for crushers. Torque limiters must be very robust, not sensitive to vibrations and offer reliable, repeatable shut off torque accuracy. Once released, fast recommissioning is then required. Many times, the torque limiter is combined with a torsional stiff coupling to get a complete power transmission package.

All these requirements are fulfilled with the Malmedie SE-GLX type coupling. It´s a combination of the Malmedie torque limiter “SE” (Safety-Coupling) and a Malmedie Gear-Coupling (like the “GLX”). Both coupling types are available as single items as well. The “SE” torque limiter can also be combined with e.g. torsional elastic couplings.

The MALMEDIE Safety-Coupling completely separates upon mechanical overload within just milliseconds (no friction, no wear). Simple and very fast re-set is done by pushing the pins of the Safety-Elements back into place. An automatic re-set option is also available. Heavy-Duty Execution.

Visit our website

Back

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM

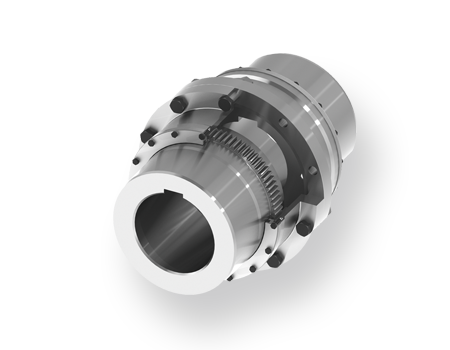

The versatile one:

The MALMEDIE GLX type gear coupling

Suitable for all kind of mining applications, the Malmedie GLX type gear couplings offer a high torque range and can be used for motor-gearbox connection or the high torque connection between the gearbox and conveyors, bucket wheels, pumps or crushers.

Specific designed seal systems prevent dust from penetrating the coupling, executions with long life grease are also available. Malmedie gear couplings can be used in underground mines (ATEX) and are available in many different executions. About 80% of the Malmedie gear couplings are tailor made to suit your needs, e.g. for drop-in replacements.

Malmedie is looking back on more than 90 years of experience in coupling design and manufacturing for a wide variety of heavy industries.

Visit our website

Back

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM

MALMEDIE INC. • 1275 GLENLIVET DRIVE • SUITE 100 • ALLENTOWN • PA 18106 • (717) 333 8177 • US@MALMEDIE.COM