Marco Ruiz Q&A: Robotics and safety

in the mining industry

wireless enabled electronic system with 2 way

communication capabilities

read interview

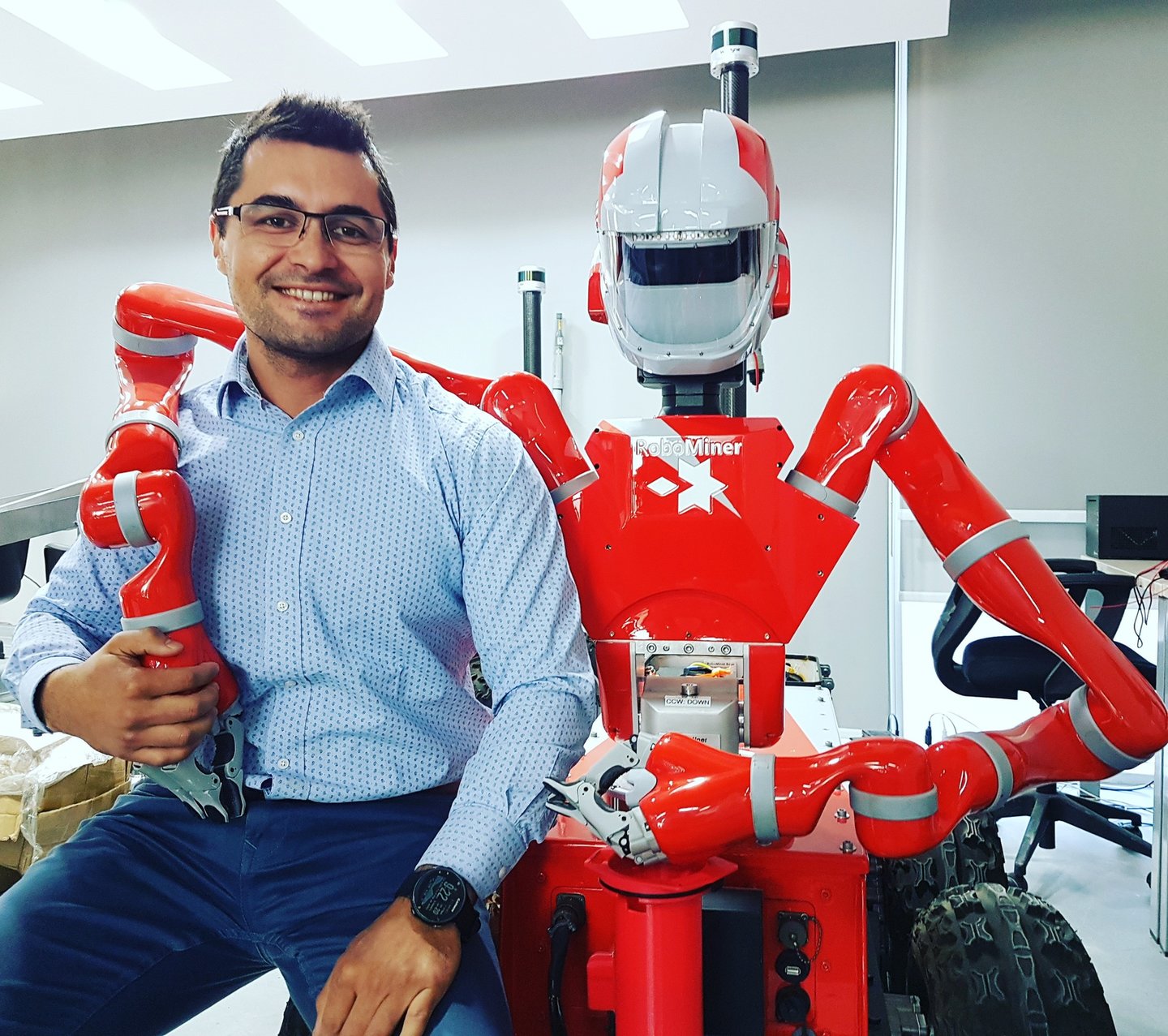

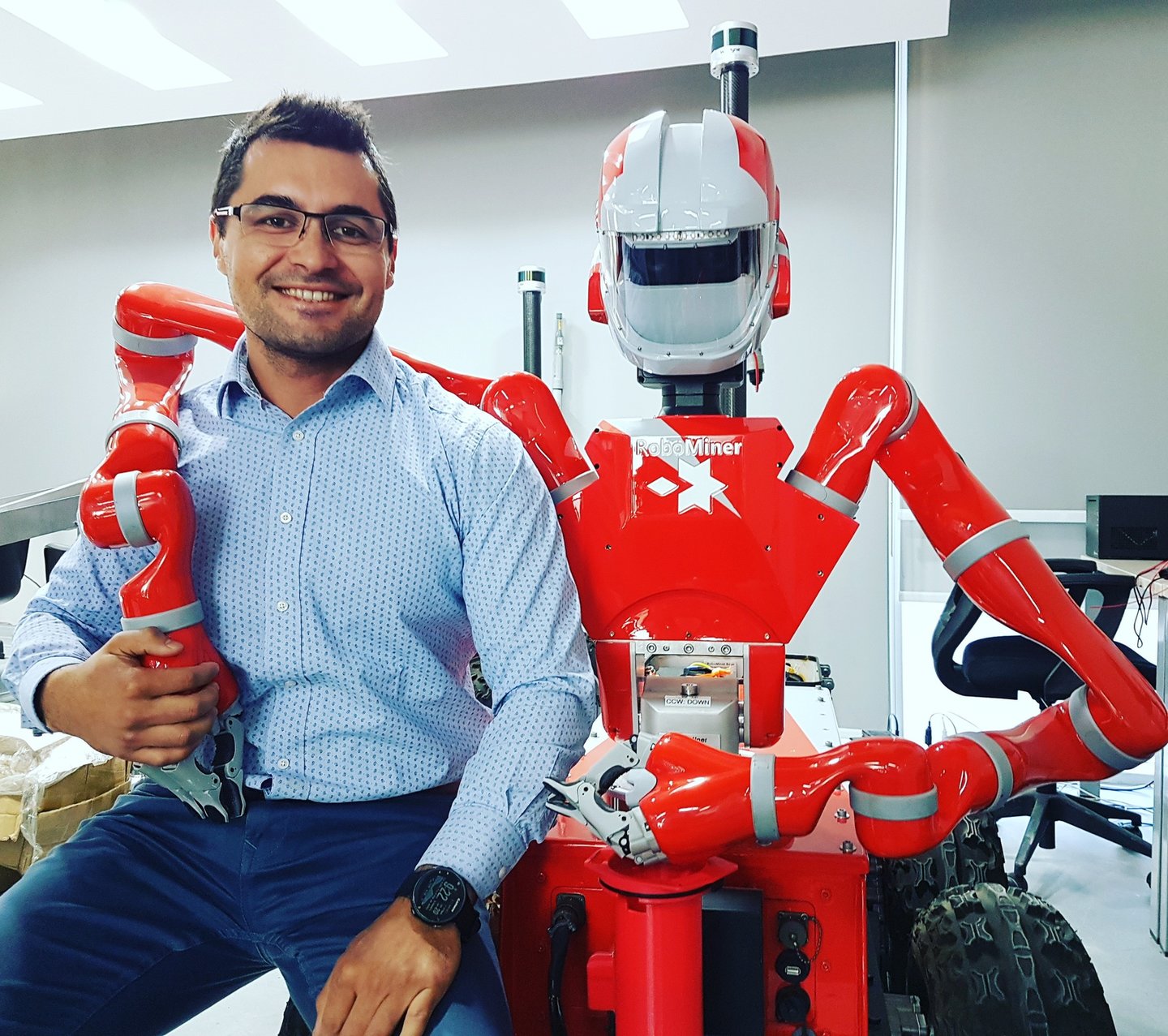

Leading the mining industry into a safer and more productive future, Enaex a leader in comprehensive rock-fragmentation services is also becoming a world leader in robotics end automation aimed at humanize mining. Enaex Robotics Director Marco Ruiz spoke to MiNE Magazine about what is the purpose behind the solution and what sets the company not only as blasting industry leaders but now technology and robotic experts and why robotics development is so important in the role of contributing to humanize mining.

What are the origins of Enaex Robotics® and why was there a need to establish a strong robotics presence?

MR: Enaex has been recognized as a global leader in comprehensive rock-fragmentation services for mining and civil works, but in 2014 we saw a new challenge within the mining industry related to robotics and teleoperation. Some customers and mines reported that they could not operate in certain site areas. They were limited in their ability to expand or proceed with operations because the environment was deemed too risky, sensitive and harmful for the workers. Mines were starting to operate in more complex environments, which created the need to develop a solution to continue with the blasting process for hard to reach resources and dangerous scenarios but with no exposure of people. To tackle this challenge, we partnered up with Stanford research institute (SRI) who are the leaders in robotics and developing robotic dexterity capabilities, and with ASI who are big players on vehicle automation systems. Resulting in the creation of a comprehensive robotized solution led by the operations of RoboMiner® and Mine iTruck®. RoboMiner® is a cutting-edge robot that handles explosives from distance through the use of wireless networks that establish connection to operate remotely with the dexterity to manipulate all elements in the priming and loading of a blast hole, working together with the Mine-iTruck®, an automized and teleoperated mobile manufacturing truck that can manufacture 20 tons of explosives in the field. These solutions combined can perform the operations we normally do in the field, but without the people on the site, enabling safe operations in places which it couldn´t be solved with traditional methods and also a direct consequence is that it enables the concept of fully autonomous mines, where teleblasting was the missing link in the chain.

How important is it to humanize mining and what is the impact on human labour for mining workers?

MR: We are focused on contributing to develop a more human blasting industry, resulting in the development of robotics at the service of humans, improving safety, improving productivity and enhance working conditions, being fully connected to the purpose of Enaex: humanise mining. All our mining operations on site are safe today; however, there are cases with challenging conditions that requires technology to solve them. Solutions like RoboMiner® and Mine-iTruck® are complimenting these operations. Enaex is shifting the way the world handles mining operations with robotic solutions. A fully automated mine will reduce the processes of the miners onsite and will move them to a safer environment. This allows the employee to work remotely while still operating the robotic technology, meaning that the decision making still lies with the human. There are projects around the world introducing this technology in other industries, with professionals driving operations in air conditioned rooms instead than directly onsite; safer, better and connected. We are not removing jobs; we are transforming jobs for the future.

Have you had success implementing this technology and what have the challenges been so far?

MR: During 2019, Enaex made the first fully remote operated blast which was a huge milestone. We are currently running an operation within a copper mine in the north of Chile. The robotic solutions we provide to our clients have the performance and effectiveness needed to shift the way how we do mining. Now, we have proved products and systems ready to operate and ready to blast dangerous zones without people on the field. Enaex in this context is the first and the only company in the world offering these kinds of solutions so we are leading the technological change within the blasting mining industry. Our next challenge will be to be as fast as possible! We have completed the milestones set for this project and are on course for the next: solutions to be more productive and faster. There is a lot of development into autonomy and artificial intelligence that will change the market in the coming years.

How are you dealing with the COVID -19 challenge and how can Enaex Robotics® assist?

MR: Most people are now working from home given the global scenario and the pandemic has had a seismic impact on many industries around the world and also in mining. COVID-19 is giving us a huge opportunity to learn and adopt the changes regarding the way technology works, this is actually reinforcing what we are targeting by using robotics. Today, people are wanting to spend more time in their private lives, with their families; Robotics and our solutions helps make this a reality; a world where the mining professional would not have to travel away from their family to go to the mine. Instead, in the future they could be operating Enaex Robotics® solutions from their office or the comfort of their home. Our technology is giving the mines flexibility and something very critical nowadays: operational continuity. Robotic technology doesn’t have any limit and COVID-19 provides us the opportunity to see our job differently for the future.

What are your main objectives in Enaex Robotics® for the customer moving forward?

MR: At Enaex, our objective is to deliver the most optimal solution to the customer. We seek to provide options that adhere to our client’s requirements, our proposal does not considers using robots for the sake of using robots, but satisfying the need of clients working in complex scenarios with very risky set ups. The customers’ need is the most important part of our business. Robotics is applying the right technology for the need of the customer. To develop a trusting, long-term relationship with clients meeting their needs and solving the challenges in our markets is vital for Enaex Robotics®. Additionally, creating innovative products such as RoboMiner® and Mine iTruck® will guide us into a more human blasting mining industry, for a safer mining environment.

Marco Ruiz Q&A: Robotics and safety in the mining industry

wireless enabled electronic system with 2 way communication capabilities

read interview

Leading the mining industry into a safer and more productive future, Enaex a leader in comprehensive rock-fragmentation services is also becoming a world leader in robotics end automation aimed at humanize mining. Enaex Robotics Director Marco Ruiz spoke to MiNE Magazine about what is the purpose behind the solution and what sets the company not only as blasting industry leaders but now technology and robotic experts and why robotics development is so important in the role of contributing to humanize mining.

What are the origins of Enaex Robotics® and why was there a need to establish a strong robotics presence?

MR: Enaex has been recognized as a global leader in comprehensive rock-fragmentation services for mining and civil works, but in 2014 we saw a new challenge within the mining industry related to robotics and teleoperation. Some customers and mines reported that they could not operate in certain site areas. They were limited in their ability to expand or proceed with operations because the environment was deemed too risky, sensitive and harmful for the workers. Mines were starting to operate in more complex environments, which created the need to develop a solution to continue with the blasting process for hard to reach resources and dangerous scenarios but with no exposure of people. To tackle this challenge, we partnered up with Stanford research institute (SRI) who are the leaders in robotics and developing robotic dexterity capabilities, and with ASI who are big players on vehicle automation systems. Resulting in the creation of a comprehensive robotized solution led by the operations of RoboMiner® and Mine iTruck®. RoboMiner® is a cutting-edge robot that handles explosives from distance through the use of wireless networks that establish connection to operate remotely with the dexterity to manipulate all elements in the priming and loading of a blast hole, working together with the Mine-iTruck®, an automized and teleoperated mobile manufacturing truck that can manufacture 20 tons of explosives in the field. These solutions combined can perform the operations we normally do in the field, but without the people on the site, enabling safe operations in places which it couldn´t be solved with traditional methods and also a direct consequence is that it enables the concept of fully autonomous mines, where teleblasting was the missing link in the chain.

How important is it to humanize mining and what is the impact on human labour for mining workers?

MR: We are focused on contributing to develop a more human blasting industry, resulting in the development of robotics at the service of humans, improving safety, improving productivity and enhance working conditions, being fully connected to the purpose of Enaex: humanise mining. All our mining operations on site are safe today; however, there are cases with challenging conditions that requires technology to solve them. Solutions like RoboMiner® and Mine-iTruck® are complimenting these operations. Enaex is shifting the way the world handles mining operations with robotic solutions. A fully automated mine will reduce the processes of the miners onsite and will move them to a safer environment. This allows the employee to work remotely while still operating the robotic technology, meaning that the decision making still lies with the human. There are projects around the world introducing this technology in other industries, with professionals driving operations in air conditioned rooms instead than directly onsite; safer, better and connected. We are not removing jobs; we are transforming jobs for the future.

Have you had success implementing this technology and what have the challenges been so far?

MR: During 2019, Enaex made the first fully remote operated blast which was a huge milestone. We are currently running an operation within a copper mine in the north of Chile. The robotic solutions we provide to our clients have the performance and effectiveness needed to shift the way how we do mining. Now, we have proved products and systems ready to operate and ready to blast dangerous zones without people on the field. Enaex in this context is the first and the only company in the world offering these kinds of solutions so we are leading the technological change within the blasting mining industry. Our next challenge will be to be as fast as possible! We have completed the milestones set for this project and are on course for the next: solutions to be more productive and faster. There is a lot of development into autonomy and artificial intelligence that will change the market in the coming years.

How are you dealing with the COVID -19 challenge and how can Enaex Robotics® assist?

MR: Most people are now working from home given the global scenario and the pandemic has had a seismic impact on many industries around the world and also in mining. COVID-19 is giving us a huge opportunity to learn and adopt the changes regarding the way technology works, this is actually reinforcing what we are targeting by using robotics. Today, people are wanting to spend more time in their private lives, with their families; Robotics and our solutions helps make this a reality; a world where the mining professional would not have to travel away from their family to go to the mine. Instead, in the future they could be operating Enaex Robotics®solutions from their office or the comfort of their home. Our technology is giving the mines flexibility and something very critical nowadays: operational continuity. Robotic technology doesn’t have any limit and COVID-19 provides us the opportunity to see our job differently for the future.

What are your main objectives in Enaex Robotics® for the customer moving forward?

MR: At Enaex, our objective is to deliver the most optimal solution to the customer. We seek to provide options that adhere to our client’s requirements, our proposal does not considers using robots for the sake of using robots, but satisfying the need of clients working in complex scenarios with very risky set ups. The customers’ need is the most important part of our business. Robotics is applying the right technology for the need of the customer. To develop a trusting, long-term relationship with clients meeting their needs and solving the challenges in our markets is vital for Enaex Robotics®. Additionally, creating innovative products such as RoboMiner® and Mine iTruck® will guide us into a more human blasting mining industry, for a safer mining environment.