The R 9600, the next generation of Liebherr hydraulic excavators, sets new standards in open pit mining equipment. The successor to the thoroughly proven and iconic R 996B is based on the successful R 9800 and fitted with the most advanced Liebherr Mining technologies.

Operating Weight 633 tonnes

Powertrain 2,500 / 2,400 kW

Bucket Capacity 37.5 m3

Liebherr Mining

Assistance Systems

Advanced onboard applications designed to support operators to become more efficient through analytics and actionable insights from live data.

The best performance. Easy.

4 On-board Assistants

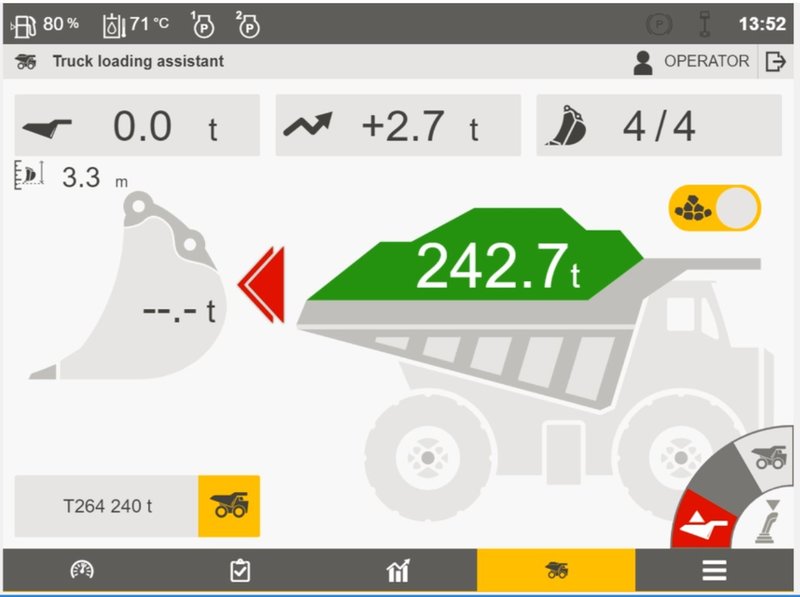

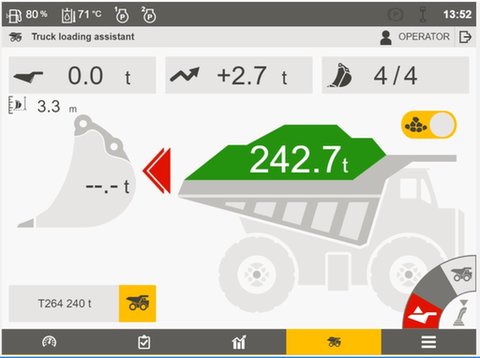

Truck Loading Assistant

Assists the operator to obtain target truck payloads.

With 99% measurement accuracy

- Measures instantaneously the bucket payload

- Provides realtime information to the operator

- Strategises the number of passes required

- Computes the best truck loading strategy

- Automatic truck recognition (optional)

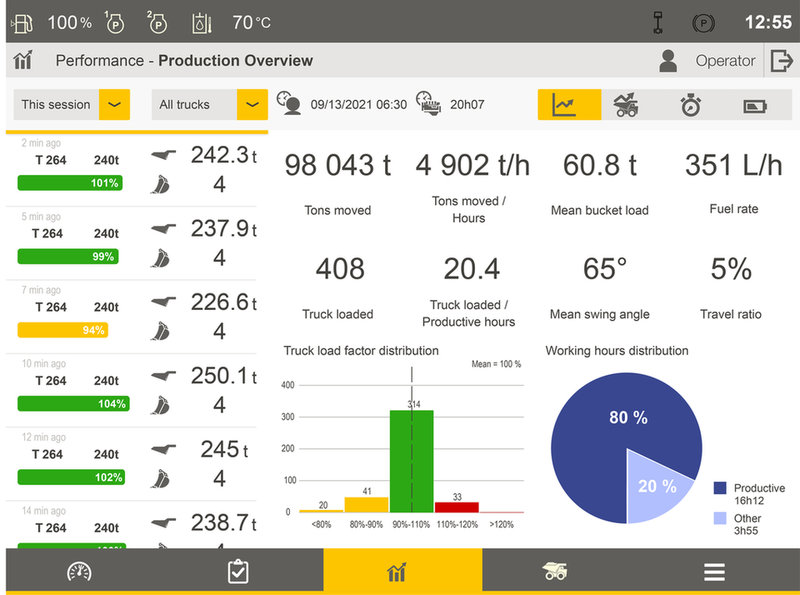

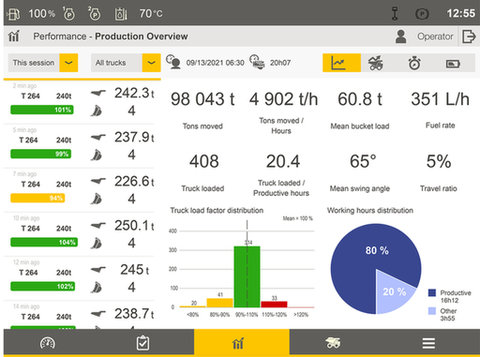

Performance Monitoring Assistant

Measures and analyses the overall performance.

Using KPIs, histograms and time-related charts

- Production indicators

- Loading indicators

- Time distribution

- Powertrain energy efficiency

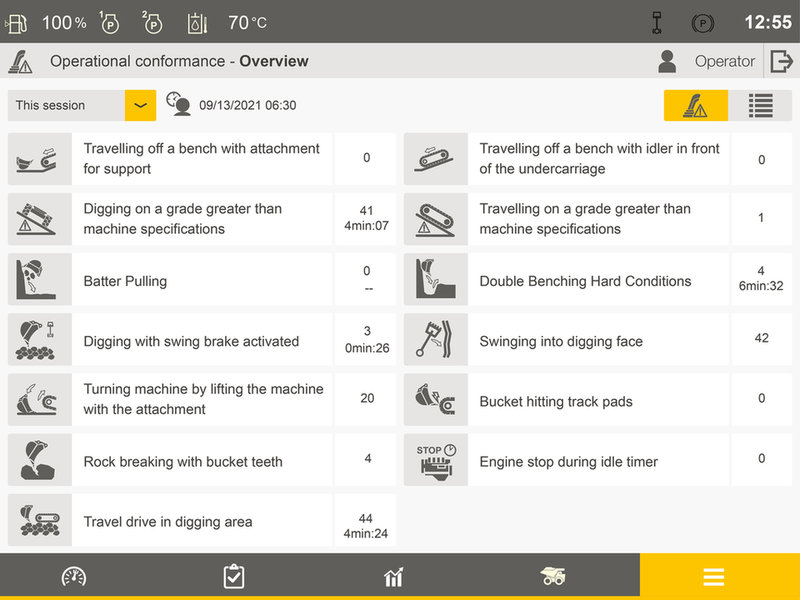

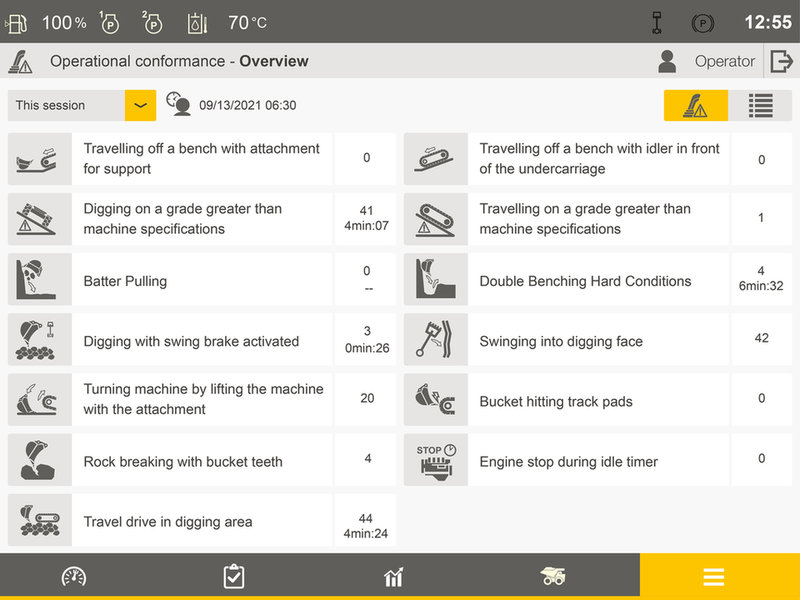

Operational Conformance Assistant

Detects and counts events to improve operator effectiveness.

Several filtering criteria to identify specific events

- Swinging into digging face

- Digging with swing brake activated

- Turning the machine with the attachment

- Bucket hitting track pads, etc.

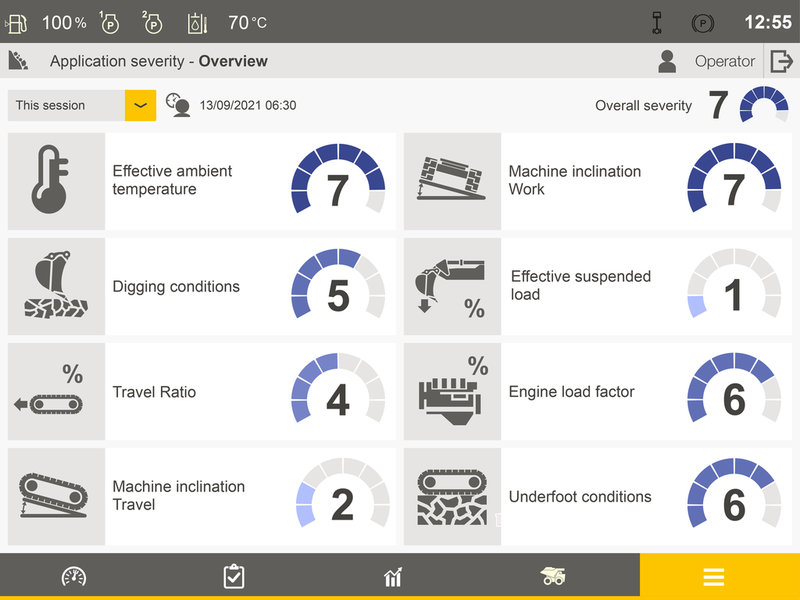

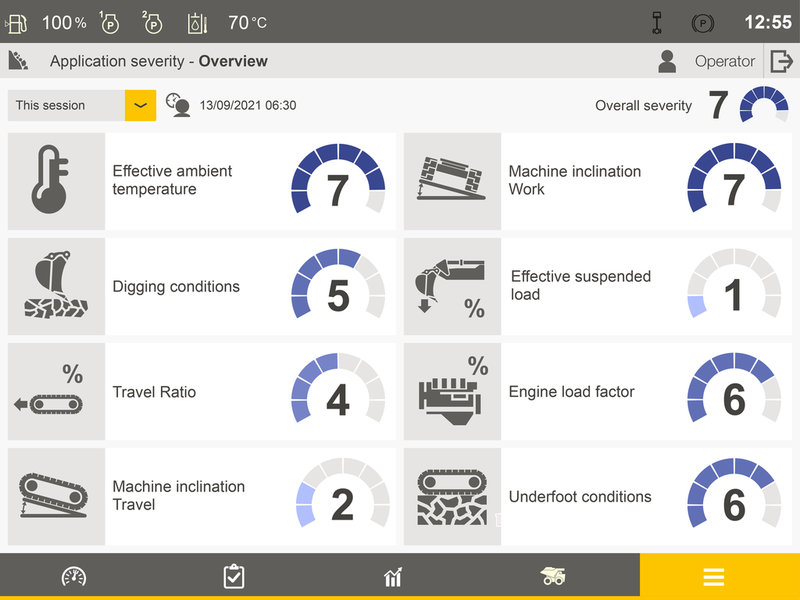

Application Severity Assistant

Quantifies application, reports severity indicators, andprovides an overall application severity score.

KPIs to indicate and display the application as sensed by the machine

- Underfoot and digging conditions

- Abrasiveness and travel ratio

- Engine load factor and temperature variation

- Machine inclination, loading, etc.

Truck Loading Assistant

Performance Monitoring Assistant

Operational Conformance Assistant

Application Severity Assistant

Automation:

Bucket Filling Assistant

The first automation product of the Liebherr hydraulic excavator portfolio allows easier bucket filling and consistent bucket fill factors, especially in blocky or hard digging conditions.

As a result, overall productivity improves while operator’s fatigue decreases.

Anti-Stalling Function

Prevents the bucket from being stalled during the digging phase.

Semi-Automatic Bucket Filling Function

Allows the machine’s electronics to realise fully automatic attachment movements.

Discover more: www.liebherr.com/nextgeneration

Truck Loading Assistant

Assists the operator to obtain target truck payloads.

With 99% measurement accuracy

- Measures instantaneously the bucket payload

- Provides realtime information to the operator

- Strategises the number of passes required

- Computes the best truck loading strategy

- Automatic truck recognition (optional)

Performance Monitoring Assistant

Measures and analyses the overall performance.

Using KPIs, histograms and time-related charts

- Production indicators

- Loading indicators

- Time distribution

- Powertrain energy efficiency

Operational Conformance Assistant

Detects and counts events to improve operator effectiveness.

Several filtering criteria to identify specific events

- Swinging into digging face

- Digging with swing brake activated

- Turning the machine with the attachment

- Bucket hitting track pads, etc.

Application Severity Assistant

Quantifies application, reports severity indicators, andprovides an overall application severity score.

KPIs to indicate and display the application as sensed by the machine

- Underfoot and digging conditions

- Abrasiveness and travel ratio

- Engine load factor and temperature variation

- Machine inclination, loading, etc.