Company Insight

Sponsored by AFS

The battle between clarity vs visibility

Standfirst...

Main image credit:

In the world of mining, fleet identification is critical to operational safety. Mines operate around the clock, with vehicles moving in tough environments and often poor lighting. To maintain effective communication and avoid accidents, every vehicle must be easily identifiable. The industry has seen a growing adoption of illuminating vehicle ID solutions, but not all lighted displays are made equal.

The purpose of illuminated IDs is to provide clear identification in low-light settings, but the way the light is used makes a significant difference. The question is: what offers better clarity and visibility without compromising safety?

The glare issue

Many traditional LED vehicle ID signs expose the LED directly to the environment. While this might sound effective, there's a critical flaw: glare.

The problems with exposed LEDs:

1. Excessive brightness

Exposed LED signs rely on powerful light sources that shine directly outward. While this creates a bright display, it often leads to excessive glare when viewed from a distance. Instead of helping, the intense light can obscure the digits on the ID, creating an effect similar to being blinded by a high-beam light - especially problematic for other vehicle operators on the site.

2. Reduced clarity

Brightness does not always equal clarity. The exposed LEDs can create light pollution that reduces contrast, making the actual ID difficult to read. This is especially true when viewed from far away, where the overwhelming light can blur the edges of the numbers or characters. A higher LUX doesn’t mean a clearer display. In mining operations, where safe communication between vehicles is crucial, the inability to clearly see an ID from a distance can be a serious safety concern.

3. Not a light source

It's important to remember that the goal of an illuminated ID is clarification, not illumination. In other words, the purpose of these IDs is to enhance visibility of vehicle numbers, not to act as a light source. Exposed LED signs can end up functioning more like headlights at a further distance rather than providing the clear identification needed for safety.

Lifespan and damage issue

When it comes to a light source, all lights have a lifespan and when that lifespan runs out what happens next? For exposed LED signs, the sign’s identity relies on each individual led to give the shape of the character or digit. When a collection of LEDs starts to fail and stop illuminating a section of a character or digit it can no longer create the shape for viewers to identify the represented ID. Because the ID is heavily reliant on the LEDs the whole display would need replacement. It is not just lifespan, but the harsh environment of mining could damage the boards LEDs. If one character segment fails, the whole sign needs replacement, which could be a costly and unreliable issue.

Backlit technology

Unlike traditional LED vehicle IDs, Rock Board® products utilize backlit LED technology. The difference lies in the way the light is delivered and distributed across the display.

The benefits of backlit Rock Board® technology:

1. Distributed illumination for reduced glare

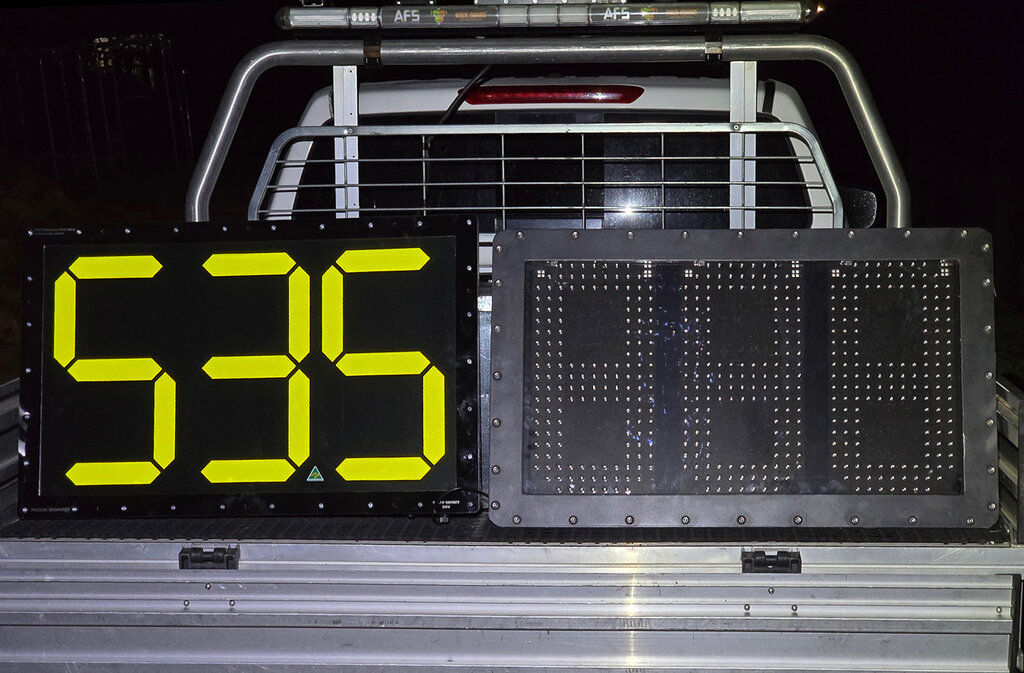

Rock Board® signs use backlit technology, where the LED light is diffused through the back of the panel to softly illuminate the characters. This distributed illumination prevents glare, ensuring that vehicle numbers are clear and readable from all angles without causing light pollution. Once the omitting LEDs start failing it does not compromise the ID shape.

2. Enhanced clarity

Backlighting ensures even distribution of light across each digit, creating high contrast between the characters and the background. This provides better definition and makes it easy for vehicle operators and site personnel to read the ID, even at a distance. Instead of fighting against a beam of light, personnel see what they need to see—sharp, well-defined characters.

3. Purposeful illumination

Rock Board® recognizes that the role of an illuminated ID is to provide nighttime clarity, not to act as a spotlight. The backlit approach is purposefully designed to illuminate only what is necessary—the asset number itself. This ensures that the identification is clear without unnecessary light scatter, making for a safer work environment during night shifts.

4. Visibility without compromise

Rock Board® signs strike the perfect balance between visibility and clarity. They are bright enough to be noticed, but not so overwhelming that they create unsafe working conditions. In environments like mines, where the risk of accidents is high, clarity is key to preventing collisions and ensuring clear, fast communication.

Impact in mining operations

The difference between exposed LED and backlit technology goes beyond theoretical discussion—it’s about real-world impact. In mining operations, safety is paramount, and proper vehicle identification plays a vital role in that safety. Imagine trying to communicate the position of a massive haul truck at night—if the identification number is blurred by glare or hard to read due to excessive brightness, confusion and delayed response times can occur, putting workers at risk.

With Rock Board®'s backlit signs, there is no ambiguity.

Many people equate brighter lights with better visibility, but in the context of vehicle identification, the goal is to be clear, not just bright. In mining sites, where dust, debris, and low light are part of everyday operations, backlit technology is the better option. It offers the right amount of light and delivers an ID.

Rock Board® products are designed by an ex-mining personnel, who understands the unique challenges of identifying vehicles in harsh conditions and has firsthand experience. By opting for backlit technology, Rock Board® provides an innovative solution that prioritizes both safety and efficiency. Exposed LEDs, fall short when it comes to practical usability. Rock Board® delivers clarity without compromise even when powered down.

Figure 1 Powered down Rock Board® RBM577 Modular LED ID Display Sign (Left) and an LED ID Sign (Right).

Traditional exposed LED IDs offer identification, illumination, glare and can create more challenges than they solve.

Rock Board® backlit LED displays deliver distributed illumination, enhanced clarity, and safety-focused design that makes a real difference in harsh mining conditions. When it comes to choosing between being seen and being understood, Rock Board® offers clear communication. Illuminate your fleet the right way—choose Rock Board®.

Contact information

Advanced Fleet Signs

16 Brewer Rd,

Canning Vale,

Western Australia, 6155,

Australia

Tel.: +61 8 9456 1414

Email: sales@afsigns.com.au

Web: www.afsigns.com.au