Maximum profitability with world class assays

XRF instruments for online elemental analysis on slurry, electrolyte, leaching solutions and wastewater

Gymnasievagen 16, SE-931 57 Skelleftea, Sweden

www.xore.se | +46 910 211 490

Benefits

Key Benefits

- Accurate data on time, all the time

- Better recovery by following process trends more closely and spotting changes earlier

- Improves productivity by keeping track of head grades, concentrates and tailings

- Return of investment within a few months (Jones et al. 1991)

- Few sensitive components gives high availability

- Oversized x-ray tube for maximum service life

- Latest available Silicon Drift Detector technology for high class assays

Choose Xore Boxray™ if you:

- Want the best available XRF analyzer technology

- Want a committed equipment provider

- Want to apply the same winning concept as some of the world’s most productive mines

- Want to respond quickly to process changes

- Have varying head grades

- Have really low metal content

- Want a future proof investment ready for tomorrows needs set by automated control algorithms

- Want an onstream analyzer with low maintenance and high uptime

Applications

We have two main business areas; Liquids Solutions and Slurry solutions.

Liquids Solutions

In Liquids Solutions we gather the applications within areas such as

- Water treatment

- Leaching plants

- Electrolytic refining

Slurry Solutions

In Slurry Solutions we focus on analyzing metal content in slurry, primarily in base metal ore processing plants.

Example applications:

- Slurry and pulp analysis in concentrator plants

- Monitoring metal content in waste water

- Monitoring metals in leaching solutions

- Monitoring metal content in electrolyte

Water treatment

Analyzing metal content in water is becoming more and more important within the mining industry. The Boxray analyzer has been used for this application since 2001 so it is safe to say that we have experience in the field. Many sites are looking for an instrument to monitor heavy metals, such as Ni, Cu, Zn, As, Se, Br, Cd, Hg, Pb. Boxray Compact is the answer to the need, the analyzer has proven performance and durability and is self-calibrating.

Slurry

The Boxray XRF analyzers are most commonly used for on-line elemental analysis on slurry in concentrator plants. With 16 or 24 samples there is plenty of capacity to monitor everything from primary mill to waste and concentrate and focus on process control. The high availability and quick measurement cycles will not only give a better view of the process today, but it is also a requirement for forward compatibility with future process control algorithms. Even the best control algorithms will underperform with inaccurate data or too few data points.

Leaching Solutions

The Boxray analyzers can also be used for on-line elemental analysis of metal content in leaching solutions, e.g. gold in cyanide leach at high temperature and high pH. The design and materials of the analyzers allow them to be used on aggressive solutions where on-line measurements would otherwise be difficult to implement.

Electrolyte

Using the Boxray Compact to monitor copper content in electrolyte is an economic way of achieving full control over e.g. a de-copperization tank house. The data from the analyzer can be displayed in the control room or retrieved automatically to the plant control system and thereby creating a fully automated de-copperization process. An additional benefit is the ability to monitor content of e.g. precious metals or contaminants from the ore or recycled electronics.

Products

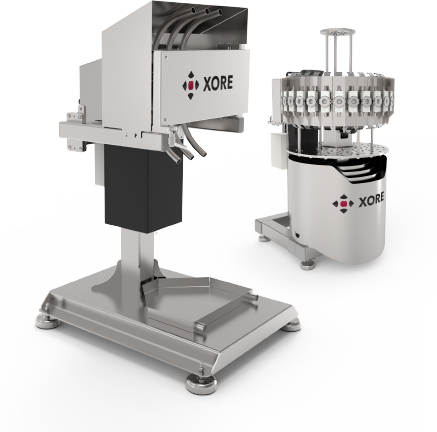

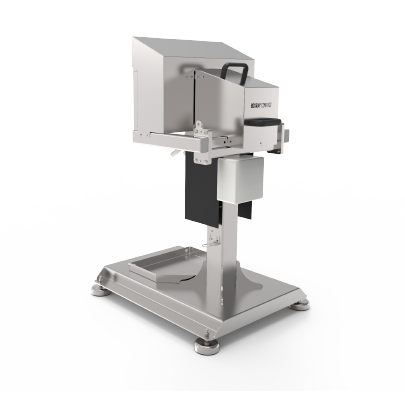

Boxray Compact

Boxray Compact is commonly used in base metal concentrator plants. Due to its high capability and versatility it is also the choice for a copper smelter, leaching plant or industrial water treatment plant. The analyzer’s slim design, high performance and possibilities for tailored sampling systems make it an affordable solution. We have over 15 years of experience in these fields as a result.

The Boxray Compact onstream analyzer has three measurement cells that are mounted on a sled that moves sideways. Two cells are used for sample streams and the third is adapted for a reference sample. Boxray Compact is equipped with a multiplex system that allows up to 16 sample streams, eight streams to each of the two measurement cells. The reference sample is analyzed on a configurable interval.

Boxray 24

Boxray 24 is the natural choice for large scale operations but it is also suitable for medium or smaller operations with rapid changes in for example head grade. Spotting trends early is key to successful process control, and receiving quick feedback on measures taken to adapt to these changes is equally important. The Boxray 24 has unrivalled short measurement time and in addition to this it only takes a few seconds to switch to the next sample.

The on-stream analyzer Boxray 24 consists of a carousel equipped with 24 measurement cells that enable a single analyzer to monitor multiple steps in the process, from ore to concentrate and tailings. As each stream has its own loop and measurement cell, there is no risk that samples will be contaminated by other streams.